We are all moving from the simple digitalization (3rd Industrial Revolution) to innovations based on multiple combinations of technologies, ushering in increasingly the 4th Industrial Revolution.

We are all moving from the simple digitalization (3rd Industrial Revolution) to innovations based on multiple combinations of technologies, ushering in increasingly the 4th Industrial Revolution.

This is forcing everyone doing business to reexamine how they will manage this changing environment. There is a need to challenge existing assumptions, question how the operating teams need to work in the future and be ready to continually innovate.

As we gather increasingly around different platforms to undertake our business, we will continue to extend and exploit ecosystems that share and relate to our existing aims, or radically challenge them to force ‘us’ to make changes to our existing business models, so to achieve different innovation outcomes that radically alter the present business landscape.

There is a major impact on business underway, which will give such a different velocity to accelerating innovation and managing increasing disruption.

On the supply side, we will create totally different ways to manage, increasing moving from internally generated outcomes to connected ones that serve existing forms and adapt to changing needs as they occur. This growing connection will radically alter existing and established industry value chains and business models. Equally, the demand side will have growing transparency, greater customer engagement and cope with different patterns of consumer behavior, as we all socially adapt to the new connected world, where speed, agility, and response, become the ‘order of the day’.

We are moving increasingly from a physical into a digital world

The movement of Industry 4.0 is combining the connected technologies inherent from the Internet of Things (IoT) with a rapidly changing understanding of the value of IT and OT. The outcomes of this movement will produce different levels of analytics, different data indicators, include even more the robotics, high-performance computing, artificial intelligence, cognitive technologies, advanced materials and augmented reality, to drive the physical act of manufacturing constantly being connected through this digital set of connections that are underway.

The key to this enablement is centered around interoperability and to achieve this is establishing the Industrial Internet of Things (IIoT) as vital. It is the ability to build around platforms will define the development of Industry 4.0 solutions as they become marketplaces and coalesce around the ecosystem these attract. As these combine, we will see emerging the hosting of many microservices all working on the platforms to solve specific problems. A highly connected world reliant on technology working together.

Where are we on this journey of establishing the Industry 4.0?

This connecting of machines becomes a massive challenge to coordinate all the different and often conflicting standards we have built up over the past years. There is a compelling need is to develop an open set of standards that unites users and service providers to leverage the ‘promise of connected technology,’ no easy task.

There are two important bodies that have been, until recently, working on developing standards. Firstly each of these consortiums has been drawing in as many of the important bodies, business and institutional along with stakeholders like Governments, to gain the necessary momentum and recognition for the change. So far The Industrial Internet Consortium (IIC) has taken a more cross-industry orientated approach while Plattform Industrie 4.0, a German initiative, is leveraging its strong roots specific to the manufacturing industry. They both have been working on identifying and establishing common standards.

Both have been working independently until late 2015 when they came together to explore ways to form a common ground between them. The drivers of this were notable companies like Bosch, Cisco, SAP, Siemens and some selected members in ICC such as GE Digital as they were participating in both and say the value in exploring a collaborative approach so a global set of standards could be developed to drive the concept of industry 4.0 to a reality.

The first critical meeting, back in late 2015, held in Zürich was more for the technical groups to explore and exchange around so as to gain an understanding of each other’s work. Up to this point, Plattform Industrie 4.0 has been working towards a Reference Architecture Model Industrie 4.0 (RAMI 4.0) in developing relative standards and what these components looked like. Whereas the Industrial Internet Consortium (ICC) has been building its Industrial Internat Reference Architecture (IIRA) with specific focuses on four viewpoints of business, usage, functional and implementation. drawn from ISO / IEC / IEEE protocols and working specifically on the cross-cutting concerns of connectivity, data management, industry analytics and interoperability. These needed ways to be combined.

Taking one example of the complexity they are facing both in manufacturing and cross-domain connections.

The challenge is this working across multiple domains. manufactured goods are only part of these. Imagine the needs for a car to build, all the manufacturing and components that need to be brought together, then we are in different stages of how the car can connect to any smart grid. Then what happens to the car at home, if it needs connecting to the power grid and charging, as well as the connecting technology built into the car when it is on the road so it is to be able to leverage technology, to ‘talk’ to other cars, navigate and be responsive to changing road and weather conditions for example. All of this needs connection through different platforms designed for the specific purpose and a vast array of ecosystems to bring this connected car to fruition. It is the magic of this word “interoperability” that requires this common ground and having open standards. Who ‘wins’ the war of ecosystems or platforms is another matter.

The two Consortiums are exploring ways to join forces

At present the two consortium parties are learning to collaborate, to exchange, to sort out differences and seek enhancements on both sides to gain a deepening understanding. It is a significant undertaking and requires this collaborative environment to feed understanding and interpret it into workable standards- no easy task but essential

Can you image what this requires? Firstly the establishing of common purpose, controlling redefining or defining multiple scopes of work to be undertaken and examined, clarifying the different structures, drawing in different audiences and determining use, value, terms, definitions, symbols, and conventions? Many of us would regard this as “dry” work but it is vital to work if we are to realize the promise of connected technology in an industrial or broader setting of our physical spaces and digital worlds.

The prize is big

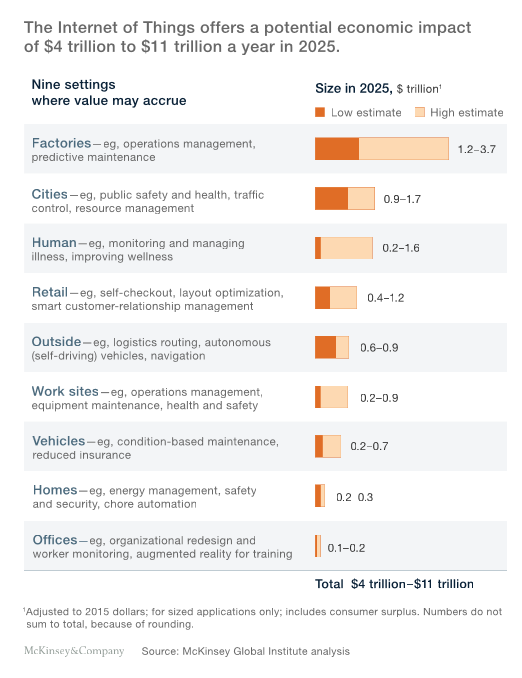

According to a recent report by McKinsey, they set about evaluating nine setting where value may accrue. See the visual below but this has a potential economic impact of $4 trillion to $11 trillion a year in 2025.

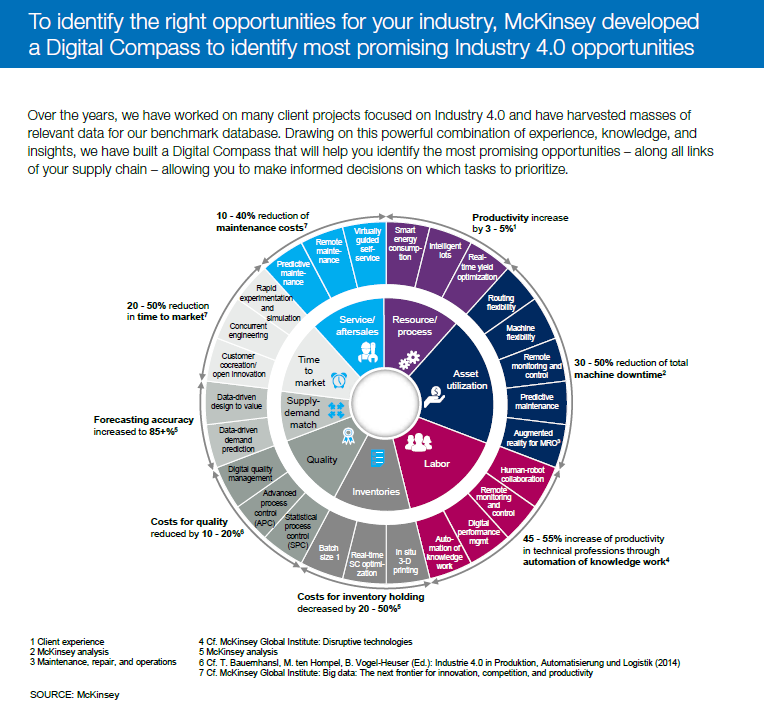

Equally, in a separate report of McKinsey, they provided a digital compass map of the Industry 4.0 levers to the eight main value drivers.

So we do need to decode the new normal

The prize seems big yet it is going to be hugely disruptive to the present way we do business. This is very much underway. Fundamental transformations are set to totally disrupt the competitor’s landscape. Out of this flows innovation on a scale that will be radical in design and impact but massive equally, in the undertaking.

There will emerge different ecosystems, even some ‘ecosystems of ecosystems’ but each of us involved or increasingly involved will need to understand Industry 4.0 in 1) its vision. We will need to identify the obstacles by 2) demystify Industry running today and explore the alternatives for a different future connected through Industry 4.0 solutions. We will struggle consistently with all the inevitable changes occurring but we equally will need to recognize 3) Industry Convergence is happening and how it drives enterprise integrations of the future and then quickly ‘tap into’ 4) the Ecosystems of new Services that will reinvent how we learn to collaborate, combine and connect to leverage these (massive) changes, so we can be equipped to adjust to the 5) New Contours of Competition. It is this evolution that we will see emerge the future value creation and opportunities to compete. Without question, it is the forming of ecosystems, platforms and the ability to find these interoperabilities to connect technology through new standards, protocols, and architecture will allow this to occur.

The major implementation barriers, obstacles and the courage to drive this are huge. The stakes are high where we aim to form the marriage between machines, vehicles, processes and our physical world is a powerful idea but this will require a consistency, dedication and deep commitment to leverage on its potential. It will require the ‘concerted’ actions of all stakeholders, with the Governments providing policy actions and within we ourselves, embracing data-driven decision making to reach its suggested potential.

We are on our way in many different initiatives, learning, and explorations.

These are building and becoming a ‘true force’ of change. It will be a long road, perhaps 10 to 20 year of concerted work where we achieve this digital ecosystem that consists of having 1) a different, more flexible and integrated value chain network of networks, 2) A Virtualized set of processes to manage work, 3) Allow in the customer interface and 4) achieve this industry collaboration that works in broader connected ways to help solve greater challenges.

A pipedream or a reality, it is the most ambitious Industry Revolution yet.

A pipedream or a reality? It is the most ambitious Industry Revolution yet. To design, establish and connect, to automate industrial systems and inspire a new connected phenomenon where it “all” interacts with each other for real-time insights, making data available at all ‘touch points.’ We are aiming for a different level of productivity and creative design, one that radically alters the existing business landscape giving physical and virtual objects an identity to monitor and interact with each other and generate real-time insights that improve the existing business processes we have today.

It is hard to imagine but there are all these disparate points that can connect through the full understanding of what platforms and ecosystems will provide. Actually, I find it a little scary I must admit on what we have to connect and how all of this will connect.

Coming from this initial summary, my next post will be a more focused look at Bosch, as one of the prime movers in IIoT then I’ll explore others progressively

I have been increasingly picking up on Bosch as one of the prime movers within this, as well as becoming a leading partner, through its own Bosch Software Innovation division. I plan to explore Bosch separately as they are becoming a potentially a “stand out” organization at the forefront of this Industry 4.0 change as they undergo their own transformation into a digitally connected company. The objective with the post hopefully will allow us to relate specifically to one company that is making this transition to an IoT company, one of a growing number seizing the opportunities.

There are a number of other examples I will also explore in the future. The one I will certainly will go back to is GE and its Predix platform, and what it is equally attempting in this digital connecting space. See a past post The Emerging Industry 4.0 Business Ecosystem for some initial background on the Industry 4.0 and some of GE’s work to connect into this.

How are IBM, SAP, Oracle, Microsoft, Fujitsu, Honeywell and numerous others all responding to the challenges of building their own platforms, leveraging ecosystems and requiring increasingly to form alliances, even with their direct competitors.

No, the space of the Industrial Internet of Things gives far more potential for ecosystem and platform management to evolve than the social ones, more written about today.

Comments are closed.