We are moving rapidly from the industrial economy, reliant on single companies simply producing specific products they believe consumers needed or simply accepted.

This approach is often giving consumers no or limited choice and this supply-side approach is about to change into one that is driven by a digital economy where all sides of the value equation are connecting. One where consumers have a greater ‘voice’ over their choice that manufacturers will need to listen to and respond accordingly.

This connected world is driving transformation inside every industry, pushing for innovation dynamism as knowledge exchanges are accelerating.

There becomes this increasing business “commons” of connecting, communicating, seeking manufacturers to collaborate far more closely, across new technology and infrastructures, that allow for a greater ‘economic diffusion’ than ever before.

Industry 4.0 is driving much of this change within industries and emerging are some powerful industrial digital ecosystems such as GE are driving to achieve, to transform their business.

There is a dramatic shift in recognizing where our future assets lie. In the past, it was heavily invested in physical ownership, the knowledge was kept within organizations and this ‘became the competitive advantage. Today that is rapidly disappearing, the knowledge is recognized to lay mostly outside the organization, it is the ‘connected minds’ across multiple stakeholders, that participate through and across new platforms and ecosystems and how these are leveraged and managed is where are looking to gain any new competitive advantage.

Recognizing your new product & service assets

Your assets are rapidly becoming your participation, engagement or ability to build platforms and ecosystems and extract the value this gives you, in unique ways but recognizing your reliance on others equally looking to achieve their ‘extracted’ value.

Platforms are becoming the brand or product means and the ecosystem is delivering the service and structuring knowledge. The new product and service equation for innovation lies in participating in both of these digitally enabled structures. They offer the enabling conditions and the ability to build connected value. The assets you build around platforms and ecosystems will be the frontier of our new competitive positions.

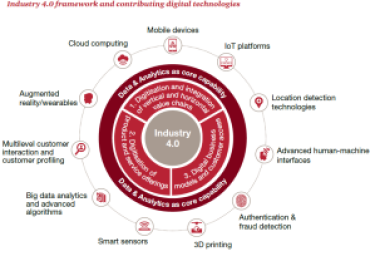

Ushering in the fourth industrial revolution has been underway for some time

This has been driven by a growing adoption by most manufacturing industries built increasingly around information and communications technology and paving the way for seeking out disruptive approaches to development, to production design and redesigning the entire logistics and value chain. The existing business models are all under change.

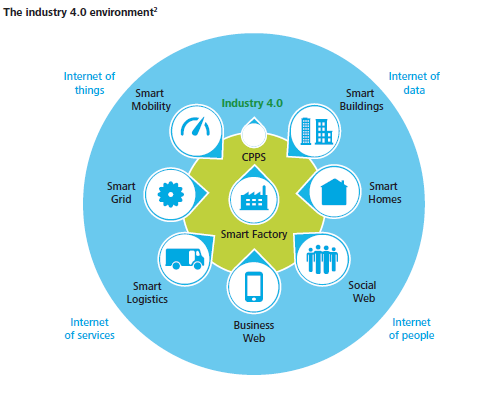

The physical world is merging with the virtual world. We are increasingly used to the internet of things, or the internet of everything and increasingly the industrial internet. They all are in the throes of digital transformation. The widespread adoption of information and communication technology (ICT) is increasingly accelerating the blurring of boundaries between the real physical world and the virtual one. The linkage is becoming increasingly Smart.

This “smartness” requires greater connection and collaborations. This is where the ‘explosion’ of platforms and ecosystems is occurring. To attempt to connect the internets of things, services, data, and people are needing radical redesigns within industries and the participants to connect all of this up.

Presently Industry 4.0 is more industrial driven but this will change and broaden out

If you take the automotive industry, for example, we are seeing virtual factories, greater automating flows through autonomous vehicles and cobots, the use of technologies like 3D printing, smart machines that can correct themselves faster than through human intervention, predictive maintenance with the heavy use of sensors and a change in the management of the production system into one of being cyber-managed.

All of this is changing work dramatically, in its overseeing, in intervening, requiring higher levels of responsiveness and anticipation, different problem-solving and correcting skills, significant logic diagnostics and yield management thinking. All of these brings increasing questioning of past management practices and as these embed inside the organization, it requires this growing ecosystem of support, reliant on technology and partners working to achieve optimization within the system.

Let us extensively explore how GE are developing their thinking around ecosystems and platforms

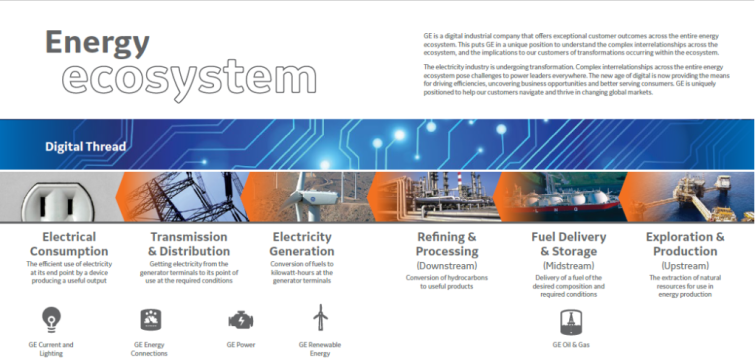

GE and its Energy Ecosystem

Equally if one looks specifically at one division with GE that operates across its energy ecosystem portfolio, you begin to grasp the complex interrelationships and the changing implications to their customers in this connected transformation.

Here the changes taking place are not only driven by advancement in technology but a growing concern for the environment and changing customer behavior, coupled with government pursuit of new policies, constant changes in fuel and energy resources and growing resource constraints. It is the need to connect across the whole ecosystem of energy that a company like GE can only do.

GE are tapping into industry-leading technologies, expertise, and global capabilities both within and outside the organization. According to GE each year $5 trillion is spent across the entire energy ecosystem globally from the capturing of the natural resources through to the final consumption by the end users. It is the multiple technologies, fuels, and industries that need to work more in collaborative ways at increasing speed and reliability. This mutual dependency requires different management

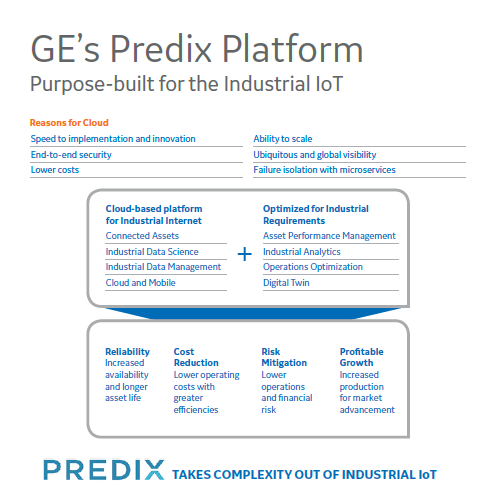

The GE platform powered by Predix

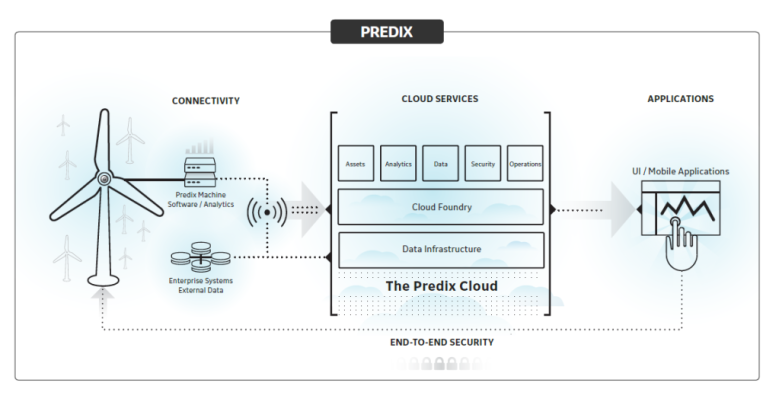

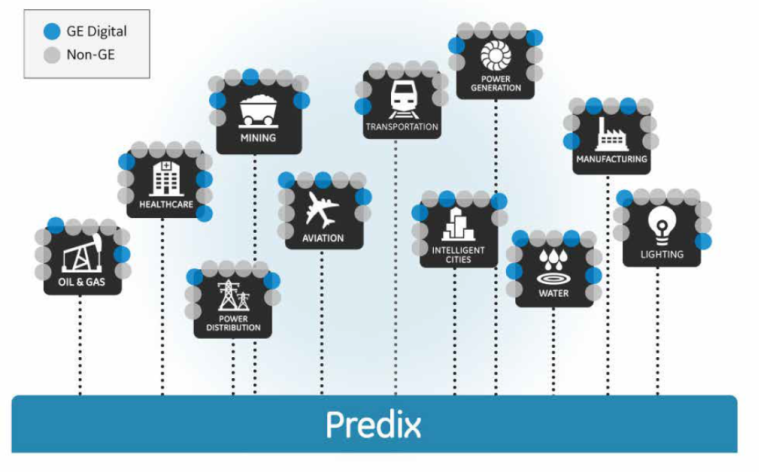

GE has shifted its business model to be a premier digital industrial company and what is critical to this is its Predix Platform, a critical operating system for the Industrial Internet by connecting industrial equipment, analyzing data, and delivering real-time insights, Predix-based apps are unleashing new levels of performance of both GE and non-GE assets.

Investment in the Industrial Internet of Things (IIoT) is expected to top $60 trillion during the next 15 years.1 And by 2020, over 50 billion assets will connect to the Internet. Predix positions itself in this Industrial Internet platform? The aim is to offer a platform that standardizes the way to enable an entire business to quickly take advantage of operational and business innovations.

The approach GE are taking in growing the ecosystem

To quote from the GE white paper: “predix-the-platform-for-the-industrial-internet-whitepaper“: “GE cannot grow the ecosystem alone, as the vision is bigger than just one company. GE partners with other technology companies, academia, consultants, and systems integrators to drive important advances in Predix functionality that businesses can leverage for their own use. Only those partners that pass rigorous audits to prove their technical and operational skills together with customer references are chosen. The result is a marketplace in which GE’s partners provide many of the new capabilities”

GE has a broad and growing set of partners – proven players in the market that are co-innovating and leveraging industry know-how and technologies. A snapshot of GE’s growing partner ecosystem can be found here:ge-digital-ecosystem-partners

The positioning of this Predix platform owned by GE has significant competitive advantage. They are aiming to attract partners, collaborators and organizations wanting to build their own solutions on the Predix platform, making it a platform of choice.

Finally, GE is also a founding member of the Industrial Internet Consortium (IIC), an open membership, not-for-profit group of public and private institutions that focuses on developing use cases and test beds; sharing best practices, reference architectures, and case studies; and influencing global standards development to ensure interoperability.

While the Industrial Internet Consortium advances the adoption of the Industrial Internet on a global scale with its cross-industry oriented approach, Plattform Industrie 4.0 has been coordinating the shaping of the Industrie 4.0-driven digital structural shift of German industry.

So will we see innovation re-invented?

The whole potential within Industry 4.0 will offer greater potential for cost efficiency, increased productivity and higher levels of preventive measures, all working towards optimizing the value chain (even more). Yet where does the customer-centered potential come in? Customer-facing solutions are increasingly possible through the exploitation of technology and the digitalization currently underway. Will manufacturers lose sight of this real need as they get caught up in this new way of optimization?

Clearly, company structures, processes, networks and profit models are all going to be challenged but the customer innovation equation needs significantly to be factored in. We are witnessing the social platform effects and these will cross over onto any manufacturing platforms with equal force. The customer needs to become the center of attention within this Industry 4.0, otherwise, it will not be the level of revolution this is expected to be

I feel product innovation will increasingly become more digital technological innovation in its solutions offered. We will achieve an even greater potential for ‘hybrid innovation’ as manufacturers learn to collaborate and extend out their offerings as collaborations and networks shape each others thinking. Cross-discipline engineering and design will be the frontrunner of a new process innovation.

The ultimate potential of this Industry 4.0 revolution that builds on technology platform and a partnership of ecosystems that we will see emerge a new “Customer Experience Value Chain” and that will be the real revolution

In Summary

Through the illustration of GE and how it is establishing its solutions around technology and the digital transformation, the strategic decisions of most manufacturers will be to invest increased resources into dedicated platforms and recognize consistently the increasing value by building their ecosystem across multiple partners. Both platform and ecosystem investment will become a major asset of any organization going forward.

As we can see with the Industry 4.0 momentum driven by this Industrial Internet Consortium shaping and setting the standards, best practices and processes of the Industrial Internet we will see higher levels of productivity and efficiency.

Yet it is the highest value we can gain from moving towards a greater “customer Experience Value Chain” as we have within our ability, thanks to technology, the means to engage, involve and provide those customer-facing solutions that are needed and increasingly expected in today’s very highly-connected world. Innovation faces considerable change in the way it adapts to all

Innovation faces considerable change in the way it adapts to all this technology, internet connections (things, people, data, objects, and systems ). It will undergo a dramatic change to adapt and adjust to a very different innovation landscape.

The need to rethink and resign around platforms and ecosystems is gathering a significant pace. Are you working through all the implications?

******

Editor’s note: In writing this the work of Deloitte, Accenture, PwC, Roland Berger, the Deloitte University Press, the Forshingsunion in Germany and the Switzerland Global Enterprise I would like to acknowledge in informing me of the enormous potential that Industry 4.0 is having in its manufacturing impact and reminding me of the significant potential, in all our hands, to transform the value equation and drive the innovation outcomes, gained from technology and digital infusion for connecting us all.

Comments are closed.