I continue to look at the world of IIoT solution platforms that are being offered to their customers which are digitally enabled, requiring connected devices to improve efficiency, productivity and increase profitability, all being provided through digital platform offerings

I continue to look at the world of IIoT solution platforms that are being offered to their customers which are digitally enabled, requiring connected devices to improve efficiency, productivity and increase profitability, all being provided through digital platform offerings

I’ve looked at Bosch and its IoT suite, Siemens and its Mindsphere, GE and its Predix platform, and Schneider Electrics with its Ecostruxure to begin to explore and understand their digital platform offering. I do need to revisit GE and its Predix platform with recent changes occurring inside the company.

I then wrote a summary of the fact that Industry is lagging but catching up in its choices of platform offering, taking three of these examples and how just within a few months this seems to be accelerating into a real race of the IIoT digital platforms to seize competitive advantage as well as I term it “taking the IIoT hill” to make sure customers align with them. A digital industrial application offering has increasingly become central to growth for many of the infrastructure providers.

This post is about ABB and their ABB Ability™ to offer a common platform across the industries they serve of a digital end-to-end set of solutions.

ABB has been investing in building their ‘digital operations’ to control, interrogate and modify the operational task in response to the external signals, mostly through distributed sensors. The aim is to transform clients activities more into software-driven activity, where the operational results in identifying trends and possible failure modes and equally, how they can transform the whole maintenance regime, to reduce downtime and anticipate potential failure.

ABB has a fairly powerful business case for being a trusted partner.

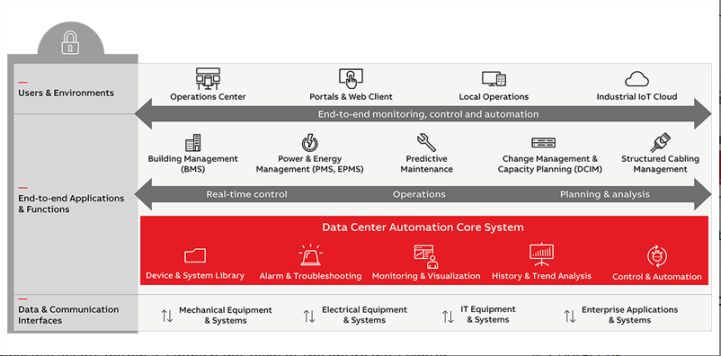

They claim to have “an installed base of more than 70,000 control systems connecting 70 million devices we have been providing digitally connected and enabled systems for a long time. A growing and exciting market we serve is the global data center industry. We are working with some of our customers in revolutionizing data center energy optimization, offering smart grid connections, off-grid electrification, power protection, and power management software. Central to the company’s strategy is integrating its power optimization systems with sensor-enabled products. The goal is to create a data-driven, intelligently automated solution that balances data center operations with the most cost-efficient power sources in real-time to maximize data center power efficiency for its customers. Intelligently connected IT reduces costs and optimizes the data center resources”. source: The case for IoT ABB

First, the sectors that ABB serve

So firstly let’s summarize ABB Ability™

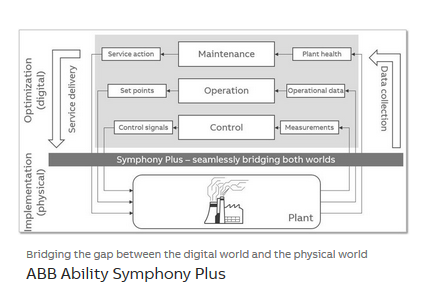

Integrated into the ABB Ability portfolio as ABB Ability™ Symphony® Plus.

ABB Ability Symphony Plus is a distributed control system designed to maximize plant efficiency and reliability through automation, integration, and optimization of the entire plant. ABB has been evolving this Symphony concept for over 35 years both with new generation enhancing as well as backward compatibility of “evolution without obsolescence” they are putting a continued store on product life-cycle management, by focusing increasing on control technology innovation and harnessing it to the digital revolution in their ABB Ability™ platform. The distributed control system (DCS) is central to their client offerings for power generation and water treatment for example. ABB has more than 6,800 Symphony DCS installations in operation all over the world and more than 4,800 of which are in power and water applications.

To quote from their website: Automation Sentinel remains the key program for life cycle system support as customers continue to upgrade and evolve their installed systems to our latest generation offerings. For power generation and water, Automation Sentinel is available via ABB Power Generation Care and ABB Water Care, offering a complete service that raises the performance of the plant’s automation and electrical assets, its operations, and maintenance staff, and the production process during the life cycle of the facility”.

To continue on what the ABB Ability Symphony Plus embodies: “it offers the essential components of a closed-loop system: sense – analyze – act, in a continuous, repetitive way”. The shift is underway to focus more on the autonomous future and a more perceive – understand – solve becomes the closed loop cycle.

Data is collected from the controlled system, the data is analyzed to gain knowledge of whether the system is behaving according to the expectations, and action is taken, if required, to influence the system’s behavior to match the expectations. As a result of a closed loop operation, the outcome will meet the set target.

Many Internet of Things (IoT) approaches focus on data collection (sense) and analysis. However, ABB is pointing out that all the value is finally generated in the physical world. Energy, material, or time is saved, or more is produced. Therefore, the knowledge gained from the analysis has to be put into action, i.e. the improvement has to be implemented. Only by closing this loop, the value is created.

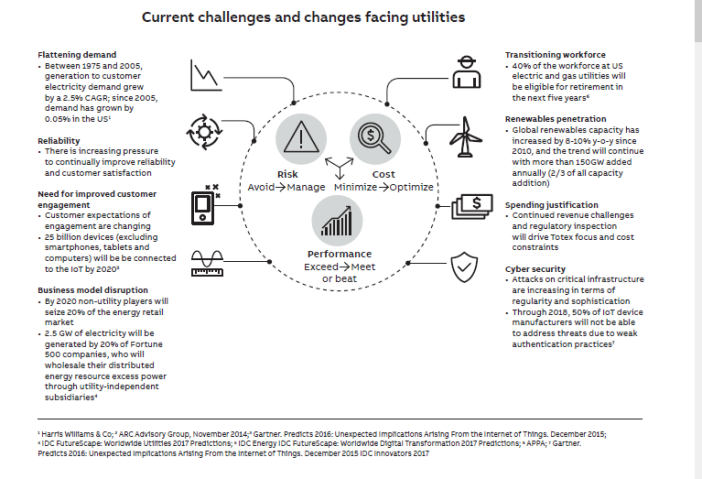

ABB provides an excellent visual of the current challenges and changes facing utilities

It is increasingly through digital solutions they can help break down some of these challenges facing the utilities. The collapse in the demand has been creating real problems for GE, Seimens, and ABB. ABB are suggesting that power and water companies that embrace digitalization gain more than 10% in productivity, maintenance and reliability improvements whereas those that neglect digitalization gain only 1 to 2% improvements.

Last year, 2017, Frost and Sullivan named ABB its 2017 Global DCS company of the year through its pioneering and leadership in the digitalization of the energy industry.The whole game is collaboration in today’s market and ABB are pushing to provide the edge over others.

The race to be top of the IIoT digital platform hill is hotting up – watch the elbows and back-stabbing.

There is this race up the digital platform offering “hill” to get greater collaborations with customers, to achieve a certain lock-in” effect as the eventual rewards are huge.

Research firm IDC forecasts that worldwide spending on the Internet of Things (IoT) will grow to $1.4 trillion in 2021 from an expected $800 billion in 2017. The largest investments are being made in areas such as manufacturing, transportation, and utilities, carving out the IIoT part as a big investment need and opportunity.

The fusing in with the emerging Industry 4.0 business ecosystem becomes important to understand as well, as it has profound implications. I have discussed in the revolution, platforms, digital and the huge impact on business in the future what is making this a very essential ‘race’ to be there, in amongst the IIoT digital platform winners. The prize is very big to be a winner.

It is interesting that all I have reviewed so far are partnering with Microsoft Azure

So to tap into the opportunities of the IoT or IIoT, companies are investing in new solutions that digitize their industrial equipment and integrate it with their broader IT environments. This is the race we are currently seeing between all suppliers of manufacturing equipment and services, my race up the IIoT digital platform hill.

The question is making the right strategic investment choices in the digital offering. What solutions are you wanting to solve with the digital offerings?

ABB are jostling to be at the front but it is a crowded leading pack

Apart from Bosch, Siemens, GE, Schneider Electrics there are plenty of others. The real offerings have only been significantly emerging in the past few years. GE and Predix lead the pack for a long time. To be honest I am not sure who is leading, who is deciding to run a different race as they recognize their value, limitations, and places to effectively compete. More will emerge on this in the months and years ahead, from me and plenty of others, seeing this digital platform race.

The above is a visual of the Data Centre Core ABB offer within their platform solution offering.

Strategic Partnerships will be essential to the winning solutions

ABB have tied in with HPE in a strategic partnership that combines ABB’s industry-leading digital offerings, ABB AbilityTM, with HPE’s innovative hybrid information technology (IT) solutions. The partnership will provide customers with solutions that generate actionable insights from vast amounts of industrial data to increase the efficiency and flexibility of their operations and create competitive advantage.

It is interesting that all platforms I have reviewed so far are partnering primarily with Microsoft Azure. I wonder why AWS is not so prominent here. I need to look into this and understand it a little better.

Back to HPE & ABB to quote from a press release ABB and HPE bring intelligence to industrial plants

“Customers will benefit from ABB’s deep domain expertise in operations technologies (OT) and HPE’s leadership in information technologies (IT). ABB and HPE will deliver joint industry solutions that merge OT and IT to turn industrial data into insights and automatic action, combining widely-adopted cloud platforms like Microsoft Azure with IT systems running in corporate data centers and at the edge of the network. Employing the right mix of IT platforms will accelerate data processing in industrial plants and at the same time enable effective control of industrial processes across locations”

“This strategic partnership marks the next level of the digital industrial transformation. Together, we will bring intelligence from cloud-based solutions to on-premises deployments in industrial plants and data centers for greater uptime, speed, and yield,” said ABB CEO Ulrich Spiesshofer. “ABB and HPE will deliver solutions that span the entire range of computing required by enterprises today, from the edge to the cloud to the core.”

These partnership races are aiming to (quote): will shape a digital industrial future where everything computes, equipping machines with intelligence to collaborate, allowing plants to flexibly adapt to changing demands, and enabling global supply chains to instantaneously react to incidents.

HPE and ABB are aiming to provide a true end-to-end experience for customers, that will include co-innovation, co-development, joint go to market and service between them.

So in summary

So ABB Ability™ is their unified, cross-industry digital capability platform that is extending the device and sensors built into it to the edge, into the cloud with all the devices, systems, solutions, services and the platform for “customers to know more, do more and do better” in more collaborative ways, offering a common offering for digital end-to-end solutions.

Research notes and sources: The material used came from ABB sites and the quotes used are from different sources of their websites on the subject of ABB Ability™ or associated offerings.